What if a Data Is Too Big to Be Opened by Parts

7 Things to Consider for Successful Spare Parts Management

Almost companies are reluctant to maintain a comprehensive spare office inventory because they fear that stocking avails like spares is counterintuitive when trying to effectively control operating costs. They expect plant managers to place ways to reduce cost while maintaining the performance and efficiency of found operations.

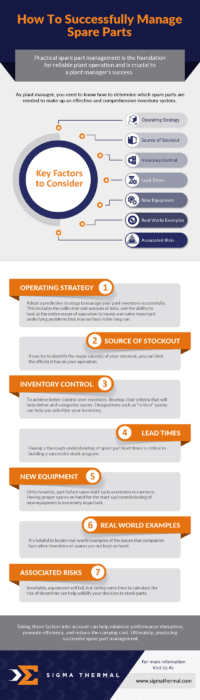

Practical spare part direction is the foundation for reliable plant operation and is crucial to a plant managers success. As plant director, you need to know how to determine which spare parts are needed to brand upwardly an effective and comprehensive inventory system. Rather than using perception to make up one's mind what's needed, it'south all-time to establish a strategic method that will adequately manage the motility and storage of your inventory.

Operating strategy, inventory control and atomic number 82 times are a few of the factors you should consider when developing or reviewing your part management system. Taking these factors into account can aid minimize performance disruption, promote efficiency, and reduce conveying cost. Ultimately, producing successful spare office management.

Operating Strategy

Equally a parts manager, yous will either operate from a predictive or reactive position. Virtually companies autumn into the habit of building their management strategy around reactive events. To successfully manage part inventory a manager should adopt a predictive strategy. While reactive management tin be beneficial during a crunch, the essence of successful management is the ability to preclude bug before they ascend.

Equally a parts manager, yous will either operate from a predictive or reactive position. Virtually companies autumn into the habit of building their management strategy around reactive events. To successfully manage part inventory a manager should adopt a predictive strategy. While reactive management tin be beneficial during a crunch, the essence of successful management is the ability to preclude bug before they ascend.

Predictive direction of spare parts includes the collection and analysis of data, and the ability to look at the entire scope of functioning to locate and solve important underlying issues that may surface in the long run. In relation to collecting and analyzing data, be certain to await out for patterns of failure that tin reveal problems that are non clearly visible. Predictive management will assist you lot to brand meliorate use of resources, cutting the time and cost associated with fixing issues.

Source of Stockout

Information technology is impossible to eliminate the nagging consequence of stockout (out of stock parts) without investing in spares. Withal, if you endeavor to identify the major cause(s) of your stockout you can limit the effects it has on your operation. Outset recording the reason(s) for out of stock parts in existent time. Additionally, review forecasted demand and expect for parts that may accept an incorrect order setting. Information technology should be noted that the most typical cause for stockout is the delay that may exist inside a supply chain (internally/externally).

Inventory Control

Your spare parts inventory does non have to be extensive to be constructive. In fact, it is unrealistic to stock large quantities of diverse parts. To attain better control over inventory, develop articulate criteria that will aid define and categorize spares. Designations such equally "critical" spares tin can help you prioritize your inventory. Recognize that terms like this are multi-dimensional, and can exist refined further. For instance, a part can be labeled as critical to the operation or disquisitional to specific car office. A higher priority may be given to i designation over another, depending on its take chances and impact if a failure should occur.

Tip: Periodically review all spare parts classifications (i.east. critical and non-disquisitional) since the classification of a part could change over time, based on replacements/substitutes that may become bachelor. A regular review of spares for excess stock can assist to reduce cost besides.

Properly storing and organizing spares in a designated, secure space is besides benign for the control of inventory. A prompting for reorder volition not have place if a part is taken without a record. As well, if new stock is placed on the shelf without a record, it cannot be accounted for. A review and assay of your storage and check-out system can reveal reasons for stock inaccuracies.

Lead Times

Having a thorough understanding of spare part lead times is disquisitional to edifice a successful stock program. Part atomic number 82 time is particularly important when determining which parts to stock. If downtime is non critical for your visitor, parts that can exist acquired rapidly and easily can exist left out of a stocking programme. However, if lost production time means a significant fiscal loss for your operation, even a day or two without a office can exist too long. Many parts with long pb times are fabricated to lodge and practise not comport expediting options. Therefore, it is best to keep parts with long lead times on hand.

Tip: Off-brand components that can exist obtained more quickly may nowadays themselves equally a viable substitute during a crisis. However, yous should keep in mind that for certain equipment, these substitute/culling parts could crusade further impairment to your equipment or system.

New Equipment is No Exception

All likewise many times nosotros hear the following from operations and maintenance mangers: "Our equipment was just installed, information technology's make new, and nosotros don't need spares." While it sounds logical for many reasons, this train of thought is wrong. There is also an assumption that vendors will supply perfectly performance, quality parts (and they typically do). Simply, unfortunately, office failure upon startup is a common occurrence.

All likewise many times nosotros hear the following from operations and maintenance mangers: "Our equipment was just installed, information technology's make new, and nosotros don't need spares." While it sounds logical for many reasons, this train of thought is wrong. There is also an assumption that vendors will supply perfectly performance, quality parts (and they typically do). Simply, unfortunately, office failure upon startup is a common occurrence.

Having proper spares on manus for the kickoff-upwards/commissioning of new equipment is extremely of import. If a role is constitute to be defective, y'all can mitigate reanimation by having spares bachelor for replacement right away.

Tip: Work with your operations department to ensure that your budget includes funds for spare parts. Equipment vendors can also provide you with a list of recommended spares; sometimes lead times will be given for each part. Utilizing this information, you tin can meliorate make up one's mind which parts need to be kept on paw.

True Stories

It may assistance to hear about a few real-world examples of issues that occurred because spares were not kept on hand–

An oriented strand board (OSB) production facility had a set of grate bars that required immediate replacement. They did not accept spare grate confined on hand, so 8,000 pounds of grate bars had to be ordered and delivered via specialty courier. Fifty-fifty with expedited delivery (which was quite expensive), production was still down for more than three full days. If these spares had been kept in stock, the expense and lost production fourth dimension could have been avoided.

In another case, a large building materials visitor discovered they had a faulty flame scanner. Despite a cost tag of less than $300, the compa

ny did not continue boosted scanners on manus. The original equipment manufacturer had the part in stock and could send it out immediately, merely the building materials company notwithstanding lost a full 24 hours of product fourth dimension while it was beingness shipped overnight. The loss of product fourth dimension during the 24 hours cost them approximately a quarter of a meg dollars.

Calculate Your Risk

Inevitably, equipment will fail but taking some time to calculate the gamble of downtime can aid solidify your decision to stock parts. Making your life a whole lot easier.

Tip: To calculate adventure, you need to know what ane 60 minutes of reanimation will toll your company. Working from this data and factoring in lead times, you can determine the cost of an unexpected shutdown. And so compare that to the cost of purchasing and storing replacement parts. You can make an informed determination based on this analysis. Keep in mind, fifty-fifty if the supplier has the part in stock, getting it to the site will price a plant a minimum of 24 hours of unscheduled downtime.

Instance: $10,000 (hourly price of reanimation) x 36 hours = $360,000

Learn More

Sigma Thermal is an experienced procedure heating systems OEM. Commitment to and support of our customers is the foundation of our business. As a part of this commitment, nosotros offer our Total Client Care Programme to all customers. With this programme nosotros tin help our clients limit the downtime and costs related to unexpected maintenance issues.

Sigma Thermal is an experienced procedure heating systems OEM. Commitment to and support of our customers is the foundation of our business. As a part of this commitment, nosotros offer our Total Client Care Programme to all customers. With this programme nosotros tin help our clients limit the downtime and costs related to unexpected maintenance issues.

Programme benefits include:

- MACT testing

- System optimization

- Operator grooming and retraining

- Full equipment inspection

- List of critical spares

Visit our Total Customer Care webpage to learn more nearly Sigma's spare function capabilities or to sign upward for Sigma's complimentary, comprehensive Total Customer Care Programme.

Source: https://www.sigmathermal.com/blog/spare-parts-management/

0 Response to "What if a Data Is Too Big to Be Opened by Parts"

Post a Comment